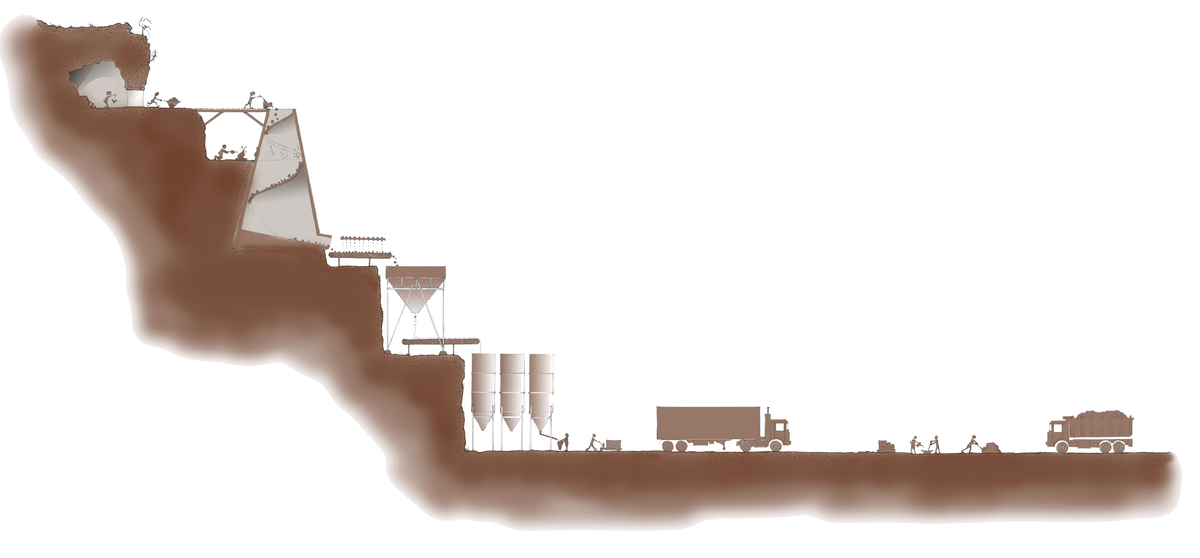

Extraction out of enclosed rooms

The lime stone comes from the dolomite region of Italy, specifically from the Trento valley. The extraction is done at five different locations near the village Tassullo. For over 200 years there has been diggings into the mountains in search of quality Marne limestone.

Combustion in the lime kiln

Limestone is burned in a lime kiln to a temperature between 800 and 1200 °C. A first cooling and grinding will already be realized by gravity inside the kiln itself.

Cooling and grinding

Coming out of the kiln the grinding will continue. The cooling is only with a very small amount of water.

Storage silos

This storage can last several months and allows thus to the lime binder to slake in the right timing. Once the lime arrives at low temperature it will be packaged as a binder (FEN XA or B-Fluid XA), or used for preparation of ready-to-use mortars (UNILIT range).

Transport in vapour-permeable bags

Given the latent reaction with lime mortars, it is important that at all times the lime remains in contact with CO2.

Preparation of the mortar on site

The mortar is prepared on site by mixing the binder and sand with clean water. The hydraulic reaction begins at that moment. By stiffening free lime is produced, which will then react in contact with air (the carbonation).